HUNCH – High School Students United with NASA to Create Hardware – offers real-world experience to students, while helping NASA replenish supplies needed on the ISS.

NASA provides materials and oversees production, and Lincoln Tech instructors will deliver the hands-on curriculum to high school graduates now training for manufacturing careers.

Lincoln Tech's selection as a HUNCH partner marks the first time NASA has worked with a postsecondary career training school.

"This is an amazing opportunity for our students and for our school," Scott Shaw, CEO of Lincoln Tech said in a statement. "For our students to know that the work they complete at our campus will soon find its way into space, and to the International Space Station, should energize and excite them about the career path they've chosen. We're honored to have been selected by NASA for such a unique, impactful opportunity."

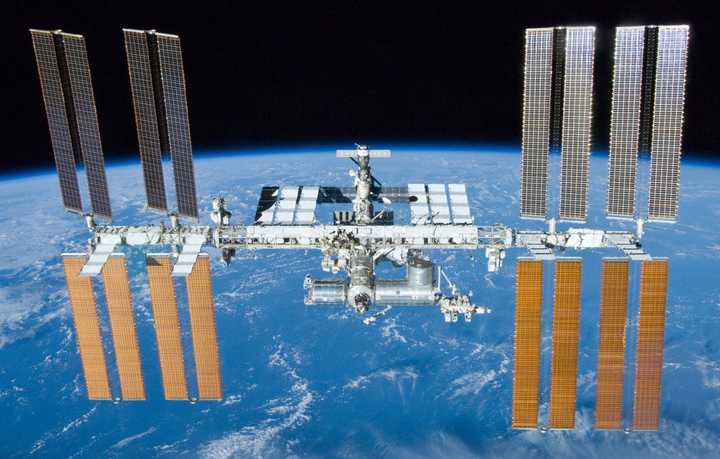

On board the International Space Station, scientific experiments conducted by NASA and other organizations from around the world are housed in specially-designed storage lockers. The pieces that hold those lockers together – studs, nuts and butterfly bolts – are manufactured on specialized CNC (Computer Numerical Control) equipment.

Lincoln Tech will begin training future machinists on 21st century manufacturing equipment that will help them create studs, nuts and butterfly bolts that hold together specialty lockers for scientific experiments.

In addition to working hands-on to manufacture the specified parts, students will also learn how to document their work according to NASA specifications. During their participation in the HUNCH program, students are considered to be official NASA HUNCH contractors.

Click here to follow Daily Voice Mahwah-Ramsey and receive free news updates.